Domestic v Commercial pizza ovens- what exactly is the difference ?

This piece is mainly concerned with those small businesses that want to start small but think they are maybe getting a poorer quality oven than those larger, obviously ‘commercial’, pizza ovens. Our partner Four Grand-Mere based in the Alsace in N E France has been making wood-fired and gas pizza and bakery ovens since the 1970’s for both domestic and commercial customers.

We as importers and installers have to know that the domestic v commercial pizza ovens we install are going to stand the test of time and can relieve some of the worries that anyone buying an expensive bit of kit has about longevity and build quality.

Let’s start with the basics-

The materials used. Broadly speaking, Four Grand-Mere make only two types of oven-one that is called C chamotte and B, a hybrid of chamotte and brick. This applies across the whole range of ovens whether they are domestic or commercial. Chamotte is a type of high alumina concrete ( Ciment Fondu) using volcanic sands and aggregates that when cast into shapes will withstand the force of high heat trying to break it down.

Ordinary Portland cement will fall apart with constant high heat and is only safe to use at temperatures under 100C. The Chamotte casting also has stainless steel micro fibres that help strengthen the cast shapes for the extreme heating and cooling cycle that all the ovens endure.

The chamotte and brick version is cast in moulds in the same way as pure chamotte but is then lined with brick slips that are bonded to the casting. Clay brick is known for its better thermal cycling and gives a mellower heat even though it may be the same temperature. Because of this extra step in the manufacturing process, the brick versions are more expensive but nevertheless nod to the original bakery ovens that every community had that were hand made in brick by specialist oven builders.

Nowadays it is possible to have the build quality of a hand made brick oven in sectional form making it much faster to install.

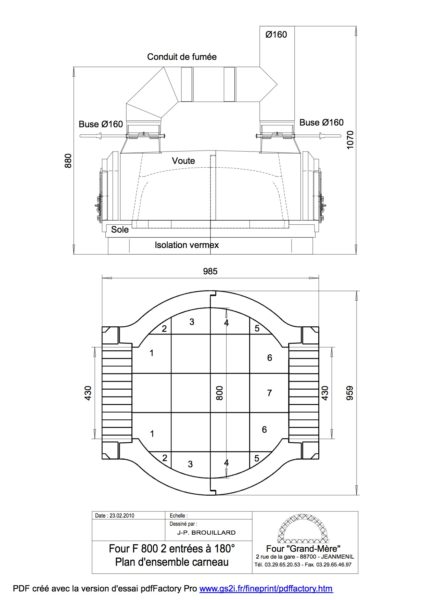

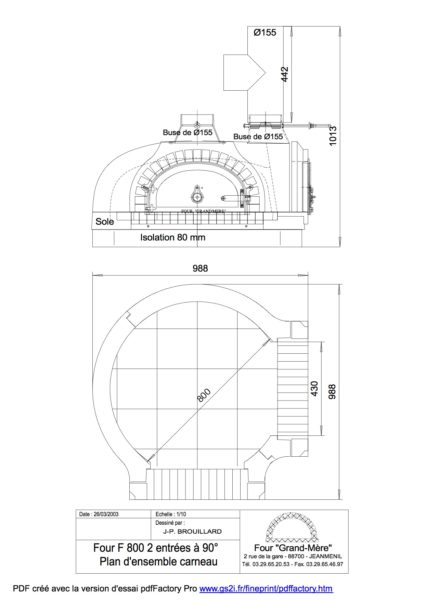

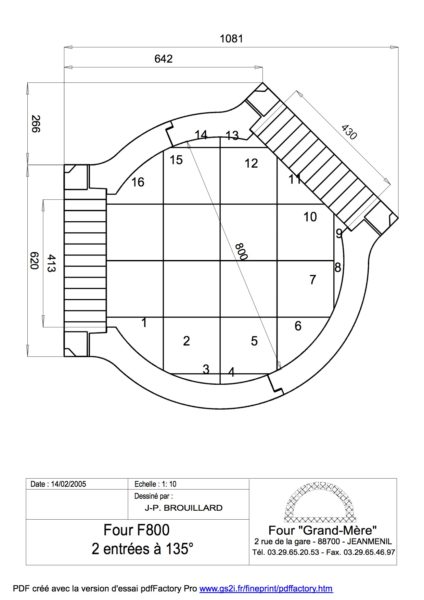

Size– The size of a pizza oven is not crucial to its function if the chef can only cook one or two pizzas at a time. In commercial environments with limited space, a compact oven that fits on a counter or in a corner is often sufficient. The number of pizzas that can be cooked simultaneously depends on the oven temperature and the chef’s ability to manage them. While a larger oven can reach higher temperatures, it may still only cook one pizza at a time unless the temperature is lowered.

Lower temperatures allow for longer cooking times and the ability to cook multiple pizzas simultaneously, which is especially important when groups of friends want their pizzas served together in cafes or pubs.

In a domestic situation, either built in the house or the garden, the oven size is usually decided by budget and the experience of the person making and cooking. It doesn’t make any sense cooking in a 120cm diameter oven for that one time in the year when you have a pizza party as most people are happy to share pizzas or wait patiently. Larger size means more wood heating it up so a balance is struck between ambition and affordability.

For the most part, domestic customers only need a 700 or 800mm internal diameter pizza oven with a few going up to 950mm, our largest domestic size.

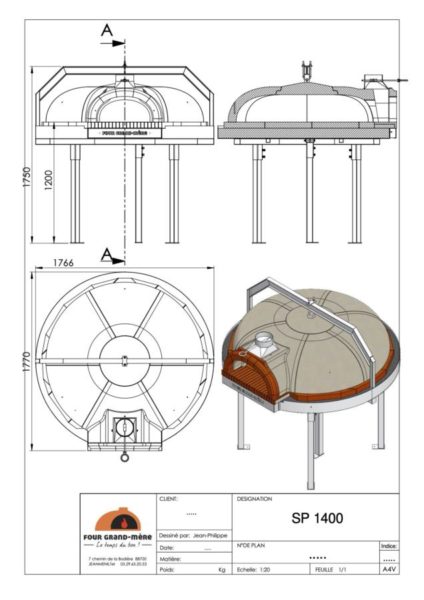

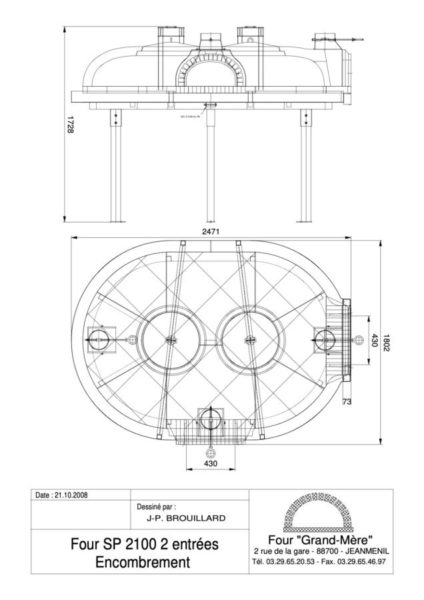

Although the materials used are the same, the commercial world needs a range of sizes and orientations that make life a little simpler. Our 950 oven say is available not only as a round 950mm diameter oven but is available in larger sizes by using interleaves that extend the length in increments or 22, 33 or 44cm . Similarly, our 1400mm round oven is extendable by adding one or more dome caps hung from steel frames so the oven wall sections rest on the dome caps enabling very large ovens with low vaults like old brick bakery ovens.

We also do a lateral oven, one that is wider than deep as a FT1350 and FT1500 so around 950mm front to back internally but 1350 or 1500mm wide. The lateral oven has been hugely popular with our commercial customers as it will fit into spaces where a round oven won’t.

Longevity and guarantees – All our domestic v commercial pizza ovens are cast the same way using the same materials so theoretically last the same amount of time. So confident are the manufacturers Four Grand-Mere of their build quality that they offer a 10 year guarantee on the domestic range. Obviously the one thing that goes in their favour is that they are probably not used every day and this is the main difference between an oven that is occasionally used and one that that is being hammered by high heat all the time, all day every day.

The commercial ovens are used and abused , with chefs throwing logs in and making the fire in the same place day in day out. This means a lot of wear and tear on very particular areas like the hearth and tiles break down eventually and crack or start pitting. The use of the oven is completely out of our control, no matter what we suggest that may improve its lifespan. We offer a year guarantee on the commercial range but if used properly, the ovens will last at least a generation if not two! Fear not, spare tiles are available even though access through the front arch may be restricted to replace those broken or work out.

I hope that gives a brief overview of the domestic v commercial pizza oven debate but if you have any specific questions please email us or fill in the enquiry form on the website and I’ll do my best to answer them.

CHOOSING BUYING PIZZA OVENS-A GOOD GUIDE