Choosing buying pizza ovens

Its a complicated business these days, so I’ve put this little guide together as even though I thought I had made all the information on my website as clear as possible, I still get phone calls to clarify a number of issues that arise when choosing buying pizza ovens for home use.

There are quite a few brands on the internet now, all competing for a slice of the relatively small UK market, with different price points and consequent quality of build. Some are ready-made whilst others are in modular form requiring assembly on site, some are high mass heavy heat-resistant concrete( chamotte), others are lightweight stainless steel with very little mass to retain heat.

With all this sometimes confusing choice, I think its best to break down what is available without mentioning individual brands and try and make sense of what’s out there. Surprisingly some people still don’t think through their purchases until its too late- buying an oven that is impossible to lift or not being able to get it through a garden gate!

Before I get started on the details of choosing buying pizza ovens please remember a few basic rules when buying almost anything-

Buying anything at a bargain price- it is a bargain for a reason! Normally because it has sat around for ages because no-one wants it but occasionally it may be damaged and/or poorly made leading to early break down-

“There is hardly anything in the world that someone cannot make a little worse and sell a little cheaper, and the people who consider price alone are that person’s lawful prey. It’s unwise to pay too much, but it’s worse to pay too little. When you pay too much, you lose a little money – that is all.

When you pay too little, you sometimes lose everything, because the thing you bought was incapable of doing the thing it was bought to do. The common law of business balance prohibits paying a little and getting a lot – it can’t be done.

If you deal with the lowest bidder, it is well to add something for the risk you run, and if you do that you will have enough to pay for something better.”

attributed to-

John Ruskin The Common Law of Business

Beware anything that is heavily marketed- anything that can’t sell itself because of quality issues is heavily marketed at a low price just to shift it. Just because you see lots of ads for a product doesn’t mean, in itself, it’s any good. It may well be a new product where marketing is essential but generally low cost /highly marketed products only sell themselves because of low cost.

The Details– logical but simple questions to ask oneself before ordering:

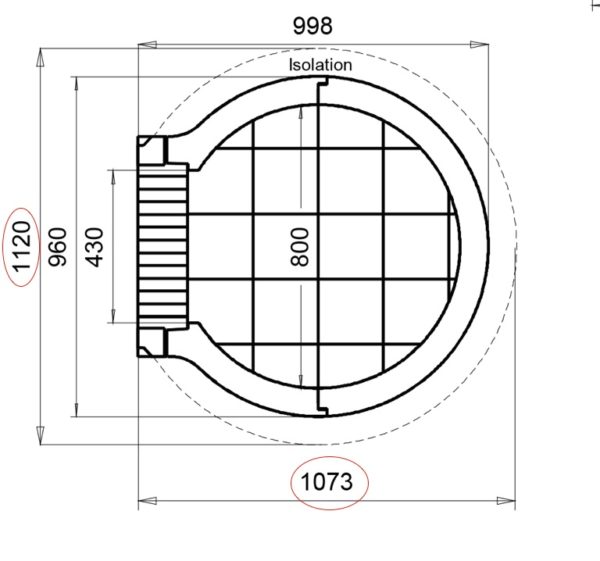

Space available– What space do I have and is it large enough for the finished installed oven?- check finished sizes of ovens with supplier and recommended base dimensions. Shown here is a tech sheet with the dimensions including insulation but remember to add up to 60mm or more all around for final finishes like renders or tiles or a shelf at the front.

Access– Can I get the oven I want into my garden- check overall dimensions of delivered goods if ready-made and unit sizes of modules if in kit form. Always measure the narrowest point in any pathway/corridor/doorway and make sure there’s enough gap for hands without injuring oneself!

Weight– Can I lift what I’ve ordered? – many ovens especially high mass concrete or brick ovens are very heavy. Ready-made ovens are especially difficult to lift and manoeuvre without moving equipment and/or several helpers.

“A friend of mine bought a cheap ready made oven online, it duly turned up a couple of days later and craned off onto the kerbside. Two days later and with 5 exhausted neighbours, the oven was inched down a side passage and round the back of the house.

That was the easy bit. It then dawned on them that they had to lift upwards of 400kg up onto the metre high base that had been build in readiness. Even for 4 strong men, that weight is impossible to lift as a dead weight so they had to improvise by wedging up each side in turn, blocking up a bit higher each time until they reached the right height.

After all that, the base was so poorly insulated that it was virtually impossible to keep hot enough for pizzas.”

Size- When choosing buying pizza ovens, surprisingly a lot of people want to order an oven that is too large, assuming that because they want to cook 3-4 ( or more) pizzas at a time, they need the space to do that.

Even experienced pizza chefs rarely cook more than that in commercial ovens, especially when they running very hot at 450-500C as they do in Naples. In a home oven most people wouldn’t be able to tend more than two for the simple reason that the dough cooks very fast and will burn unless moved constantly. Cooking three is like juggling with your eyes closed, near on impossible unless you’re running the oven at 300-350C to give you more time.

For most home installations, I would recommend a 700 or 800mm internal diameter oven and rarely a 950mm or above. If you do a lot of bread baking like many who start micro bakery businesses from home then I would say it would be justified as the extra fuel needed to fire the larger oven is negligible but the extra loaves baked on one firing makes financial sense.

“ I had a job to build a bespoke hand-made brick oven and outdoor kitchen for a client and during the construction, I had started to form a 1 metre internal diameter dome from firebricks cut in half. Three or four courses in, he came back from work one evening and reminded me about a discussion we had about the oven I had built at home that was 1.2m wide internally.

He said that he wanted it the same size as mine even though I’d admitted that I thought what I had build was too large for my home use. Next day I demolished what I had built so far and rebuilt it larger, finished the job and handed over the oven and outdoor kitchen.

A week or so later he called me after a pizza party one weekend and told me he regretted not taking my advice as the smaller oven would have been fine and that it had taken quite a lot of wood to get the large oven up to temperature and being inexperienced had burnt a few pizzas as he had tried to cook too many at once.”

Price- this is often the hardest part of the process to get right when buying choosing pizza ovens. As a rule, the more you spend when choosing and buying the better the quality but the price/quality equation tends to plateaux out at a certain point amongst the best ovens made in the EU.

For most, the equation is compromised by a fixed budget that may or may not be realistic but the decision is certainly skewed by the presence of a lot of cheap ovens that make well-made and long-lasting ovens seem expensive.

This is often compounded by impatience- rather than save up the extra to buy a good quality oven, I sometimes get people complaining about how expensive my ovens are and even accuse me of not having an oven in their budget.

We’ve chosen to sell a particular make of oven because they are incredibly well made, thought through and have a large enough range to encompass both domestic and commercial needs.

From a business point of view, We don’t want to be going back to jobs hundreds of miles away because of material breakdown. We know our Grand-Mere ovens will probably outlast my customers and would theoretically last for generations.

“My advice then is always buy the best you can afford and if you can’t afford it, wait until you can and you will be rewarded with an investment that will repay you in ease of use, lack of trouble and hopefully pure enjoyment.”

Mass- The ovens mass more or less dictates how long it will retain heat for. Old bakery ovens had a very high mass, often two or three bricks thick coupled with relatively poor insulating properties. In practice this meant long firing times of a day or two using stacks of dry wood until the brick mass was saturated with heat.

Once saturated, the baker could then regulate the internal temperature by leaving the door off until he/she was satisfied it was ready for baking. These days, oven manufacturers have been able to reduce the mass and hence cost and weight by increasing the efficiency of the insulation so that with the best ovens, firing is reduced to an hour or so and heat loss is only a few degrees an hour.

This begs a larger question- do you need the high mass for home use?

This really depends on what you do with the oven. Because heat is lost very slowly, the temperature is much steadier than an electric kitchen oven making it perfect for bread and general dough baking. The slowly cooling oven can be used for a wide range of cooking from high heat pizza baking at one extreme and low and slow cooked roasts and stews at the other. The final cooling is perfect for drying and smoking foods.

The latest trend is to reduce the mass to virtually nothing and use thick stainless steel plate coupled with efficient insulation to make an oven that heats up very quickly, often minutes, but cools relatively quickly.

The innovation has brought a big saving in time so that for high heat pizza baking, you don’t have to wait long for the oven to heat up and with the saving in fuel cost, you don’t feel bad about walking away from the oven after your cooking session and wasting all the heat you’ve loving built up in your high mass oven.

“I still prefer the ritual of building the fire and getting to know the habits of a high mass oven, it somehow feels more connected to an older time-rich tradition. It slows you down and makes you appreciate the food that comes out, the richness of slow cooking and the smoky bitter tang of slightly charred edges.”

Hearth height- When building your base try and aim for a working hearth height of around 1200mm unless you’re particularly short or tall. It saves your back from straining and makes it much easier to slide your food in and out when you can see what you’re doing. Many ovens in the middle east are set on the floor as women sit cross-legged while prepping and baking but in the west we generally stand for almost all activities!

Dome Height- Traditionally the dome height (DH) was set by its relation to the entry arch (EA) for efficiency of burn. The equation would be DHx66%=EA so a dome height of 450mm would have an entry arch of 297mm

This no longer applies to every oven especially bakery ovens which have a relatively low dome height. French ovens tend to have a lower dome height compared with Italian ovens- its quite common to have 73% relation, 297mm dome height to 217mm entry arch on small ovens which still work exceptionally well.

“We offer a choice of dome height, a low standard height and a ‘raised’ option that is 75mm higher than standard. This is achieved by increasing the base height by 75mm using a ring and using the standard dome on top. Its useful for roasting large game like goose where the standard height would be too close to the food.”

Insulation- Next to mass, good insulation is the key to a properly working efficient oven. Imagine your house without insulation or going out in winter without a coat and you’ll soon realise that if one tries to pump heat into a structure and its losing it at the same rate then it will never heat up.

In addition to keeping the heat in the mass of the oven, it also prevents the outer protective shell like render or tiles from becoming dangerous to touch. Aim for a minimum of two layers of ceramic fibre insulation plus an insulated rigid coat of vermex, a cement and vermiculite( micafil) mixture laid over the fibre to not only add insulation but also give a rigid base for protective render coats or tiles.

Aim for around 80-100mm total thickness under the hearth and over the dome and remember to add this figure to the external dome measurement when calculating your base size. When the internal mass is a raging 400C the outside temp of your finished layer should be below 40C.

When there is still moisture in the structure after building the oven, the external temperature may still be high as water vapour is trying to escape. Once this is driven off and the structure inside dry, you’ll find the external temperature falls off dramatically and may read as low as 20C.

“ We use an 80mm slab of Vermex under the hearth plus two layers of ceramic fibre that come with our ovens, one plain the other with an aluminium foil coating that reflects heat back in. In addition we add around 30-40mm of Vermex under the final Hydraulic Lime render to give a rigid basecoat and add further insulation.

Our ovens also have a thick insulated door to retain heat after baking so the whole structure may lose only 7C/hr if left overnight. It makes it easier to light an already warm oven if you keep a few logs to dry in the oven overnight.”

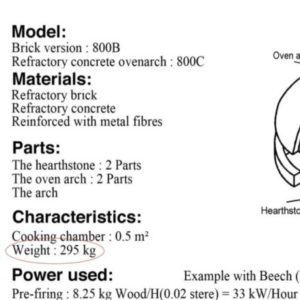

Brick or Chamotte Dome- Brick especially firebrick is an expensive specialist brick for high heat applications, usually made from around 40% alumina clay, the best for heat retention and resistance to thermal shock in wood-fired ovens. Chamotte is a volcanic aggregate based concrete that uses Ciment Fondu, a heat stable cement that is also high in alumina.

Both work well and almost all the current oven brands use Chamotte as it’s cheaper to produce once moulds have been made of the oven sections. Our expensive hand-made commercial ovens use halved 50mm thick fireclay bricks giving a dome thickness of 110mm with plenty of mass to hold heat for long periods.

” Our unique oven range comprises a choice of all chamotte dome or a more expensive combination of chamotte and brick that gives better thermal shock resistance. Most of our range have natural fireclay tile hearths and entry arches and are bedded with a thin fireclay paste making them easy to replace in case of damage.”

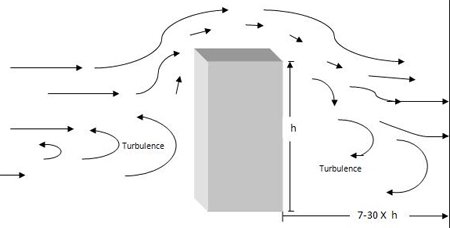

Position and siting outdoors- Sometimes one doesn’t really have a choice but if possible with any live flame, whether a BBQ, firepit or pizza oven, it’s best to site it in a sheltered position, out of the way of prevailing winds or fire up on a still calm day.

Ovens close to a tall building often suffer from turbulence caused by wind circulating in vortices, creating problems for emissions from the flue. Wind blowing directly into the mouth of the oven causes ‘blow back’, where smoke that would normally go straight up the flue ends up being blown out of the entry arch and circulating in front of the oven.

Choosing buying pizza ovens- indoor siting

For commercial outlets, oven siting is often guided by the interior design and the theatre of cooking. Owners quite rightly want customers to see the flames of the oven as they arrive, reassuring them of the authenticity and transparency of the cooking process.

This is all fine but one thing that is often overlooked in open theatre kitchens is the negative air pressure instigated by the extraction hoods over other appliances. When on full, the air pressure can lead to smoke being pulled out of the oven mouth instead of going up the flue.

Most HETAS approved flue installers will point out that there must be replacement air equal or exceeding the volume of air going out of the extraction system.

On our tech sheets ( see figure above), there are figures for the air requirement of each oven measured in m3/hr. This figure is extremely important and guides the installer so smoke will go up the flue rather than back into the restaurant kitchen.

With so many restaurants having to comply with energy saving regulations, many are sealed up against cold draughts meaning even less replacement air than before. Where necessary always arrange enough air through the HVAC system and deliver it as close to the oven mouth as possible.

Checklist for Choosing Buying Pizza Ovens-

- Space available

- Access

- Weight

- Size

- Price

- Mass

- Hearth Height

- Dome Height

- Insulation

- Brick or chamotte dome

- Position

- NOTES