A potted history of Wood-fired ovens-

We stand in a long tradition of wood-fired oven designing and building going back to remains found at the Roman city of Pompeii, near modern Naples, Italy. Wood-fired ovens in various forms, mostly unfired clay, probably existed for thousands of years before but the existing ovens have given us a model for construction and design detail that has been built on and refined over succeeding generations.

Wood-fired ovens can be found in every culture that has access to natural fuel as a resource and grain as a food. The building materials used vary from region to region but one thing they have in common is their refractory nature; they hold heat for extended periods without degrading, enabling successive batches of bread to be cooked on one heating cycle. Today, modern high alumina clays and crushed firebrick are formed into shapes, brick, tile or segment, and fired to give a stable product resistant to temperatures up to 1700C. These form the basis of brick built ovens.

Advances in refractory cement have led to the development of a new generation of oven core, one that has the same heat holding capacity as brick but in a modular form that is convenient to handle and build without any specialist skills.

The Italians have led the way in making these quick-fire ovens accessible to millions of people worldwide whilst the French have kept to traditional low vaulted high mass masonry ovens which are suited to both bread and pizza and make superb, very adaptable cooking environments.

Following this tradition, Four Grand-Mere ovens are well insulated with two or more layers of high density ceramic fibre as opposed to thick layers of sand or salt found in historic bakery ovens.

Following this tradition, Four Grand-Mere ovens are well insulated with two or more layers of high density ceramic fibre as opposed to thick layers of sand or salt found in historic bakery ovens.

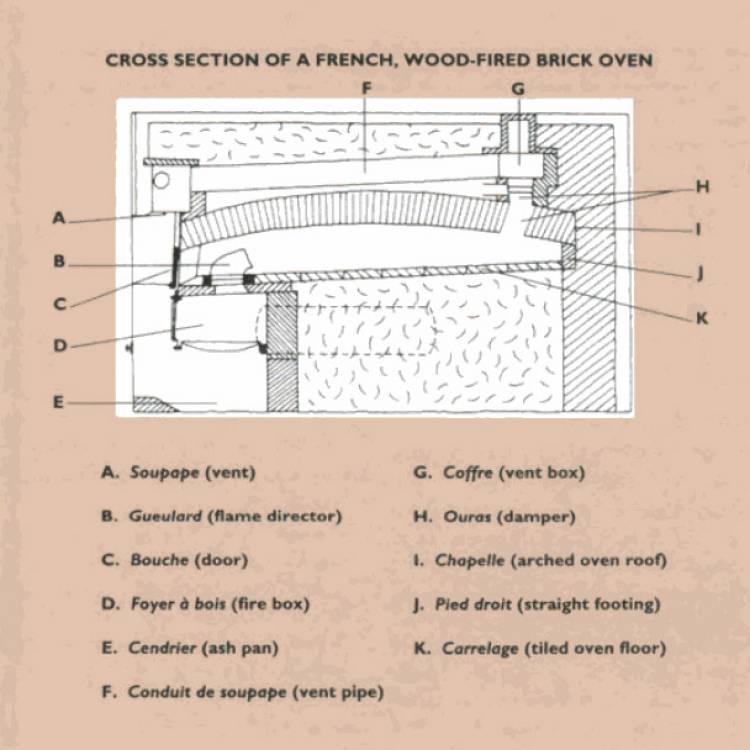

By using modern high performance refractory materials, the oven mass can be reduced from several bricks thick to a mere 60-100mm. There is a trade off as the old high mass ovens relied on the heat soaking through the whole structure with firings taking as long as 3-4 hours sometimes longer and once soaked, the oven would cool slowly enabling batches of bread to be baked before needing to fire again. Firing times for modern well insulated ovens are down to 1-2 hours and keep the heat almost as well if the mouth and flue can be isolated with an insulated door and a damper.

The ‘Gueulard’ bakery oven was developed so that the firebox could be separate from the baking chamber meaning that heat can be transferred without losing productivity- with a firebox underneath or to one side, the throat or gueulard, acts as an entry point for the jet of flames that be kept running by adding fuel as necessary and controlling the power by throttling the air intake like a wood-burning stove.

History of wood-fired ovens- ‘Banal’ or common ( French, from Middle French, of compulsory feudal service, possessed in common, commonplace, from ‘ban’ )

The old ‘Banal’ or common ovens of France that were exported to the UK along with the Norman invasion meant that villagers had no specific rights to bake their own bread and had to pay to use the common oven owned by the local Lord or landowner. The whole feudal system was fortunately overthrown and by the 17thC many houses had their own small oven tucked into the side of the fireplace so that any smoke from burning wood would go straight up the chimney.

Luckily today, we all have access to these wood-fired ovens to bake whatever we like and in a form that is relatively cheap and lightweight to install.

We can still build ovens in a traditional way using firebrick and heat stable mortar either in the form of a wood-fired pizza oven or a low-vaulted bakery oven. The materials are easily available but takes some skill to build correctly.

If you have a project that requires a wood-fired oven either hand-made or pre-cast, please get in contact and we will advise you of the best size and shape for your particular needs.